It can be mounted anywhere on the device. Ejectors usually don’t have space issues due its lightweight and easy handling.Ejector eliminates the chances of fire or explosion as there are no moving parts in it.It helps to provide continuous flow through suction media.Due to the multiple nozzles, it is used to reduce the steam consumption by 9-17 % as compared to the single-stage ejector and thus it is more efficient. In addition to this, the initial cost is high and the evacuation time is very short.

On the other hand, multi-stage ejectors give high suction flowrate and generate low noise.It is mainly used to achieve high compression ratios.

It is preferred in one set of design condition due to its single nozzle. It is used in critical as well as non-critical flow conditions. Also, the evacuation time is short and the noise generation is high.

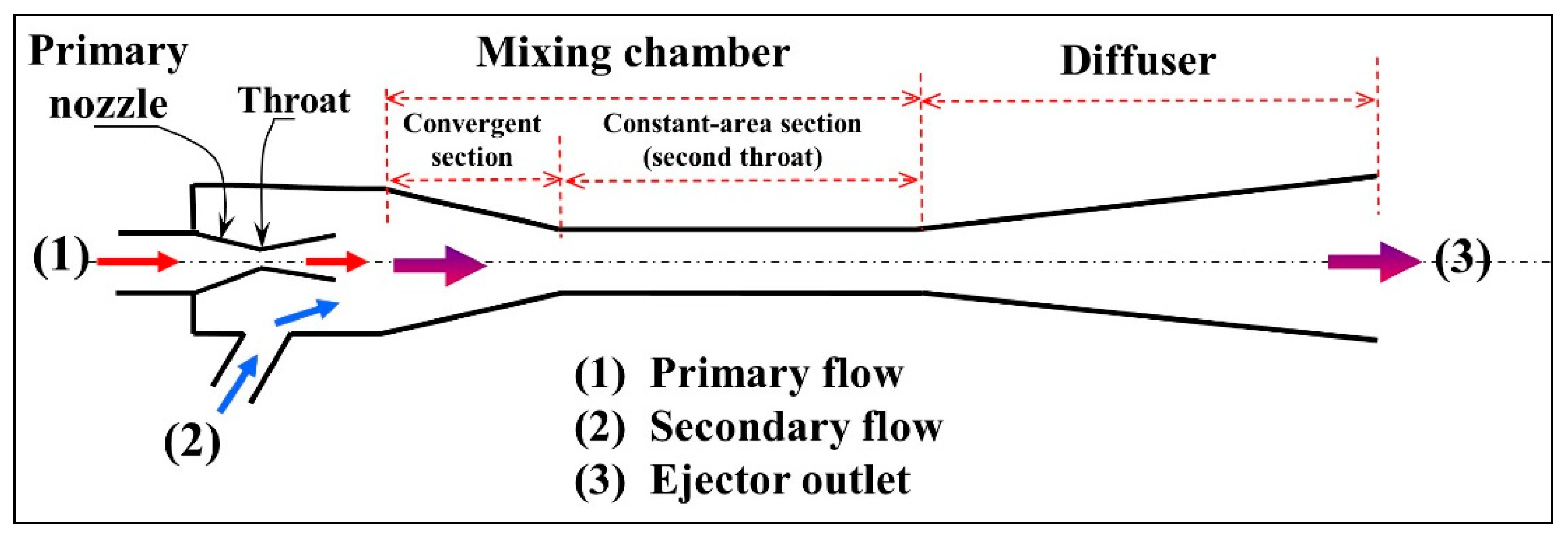

In the case of vacuum jet ejectors, due to their static and compact structure, there will be less wear and tear.In this way, waste gas (flare gas) can be recovered and added to the production.įigure 5 : Steam Jet Ejector mounted on Vessel As motive fluid flows through a nozzle, it expands at high pressure and reduces the velocity of the fluid. It is accomplished through adiabatic expansion from the supply pressure of the motive fluid to the suction pressure load created in the suction chamber. In general, ejectors convert the pressure energy (potential energy) of the motive fluid to velocity energy (kinetic energy).Once the motive fluid passed through the nozzle, due to a change in cross sectional flow area (cone shape after nozzle), the compressed fluid slows down and the recovered gas obtained in suction chamber will be discharged with the help of a diffuser (yellow arrow fig 4). During the process, motive fluid is compressed and accelerated. Afterward, it is passed through the nozzle. Motive fluid is provided through the inlet (yellow arrow in fig.4) of the ejector and the low pressure flare gas from the process vessel or reactor (yellow arrow fig.Motive fluid can be anything that further can be compressed by ejector.

0 kommentar(er)

0 kommentar(er)